[Q3] Protocols in Making Electrical Gadgets

Lesson: Protocols in Making Electrical Gadgets

By: Pj Miana

Today, we're

going to embark on an exciting journey into the world of making electrical

gadgets. Whether it's a simple flashlight or a complex electronic device, there

are certain protocols – general processes – that engineers and designers follow

to create these amazing inventions. Let's explore some of these protocols step

by step.

1.

Conceptualization:

Every great

invention starts with an idea. Engineers and inventors brainstorm to come up

with concepts for new electrical gadgets. This could involve identifying a

problem that needs solving or thinking of ways to improve existing gadgets.

2. Research

and Development:

Once an idea is

formed, it's time to dive into research and development. Engineers study

similar products on the market, analyze materials and technologies, and conduct

experiments to test the feasibility of their concepts. This stage may involve

prototyping – creating preliminary versions of the gadget to see how it works

in real life.

3. Design:

With a solid

understanding of the concept and its feasibility, engineers move on to the

design phase. This involves creating detailed plans and blueprints for the

electrical gadget, specifying its components, dimensions, and how they will fit

together. Design software and tools are often used to create precise diagrams

and schematics.

4. Component

Procurement:

Once the design

is finalized, it's time to gather the necessary components. This could include

electronic parts like resistors, capacitors, and integrated circuits, as well

as mechanical parts like casings and connectors. Engineers must ensure that all

components meet the required specifications and standards.

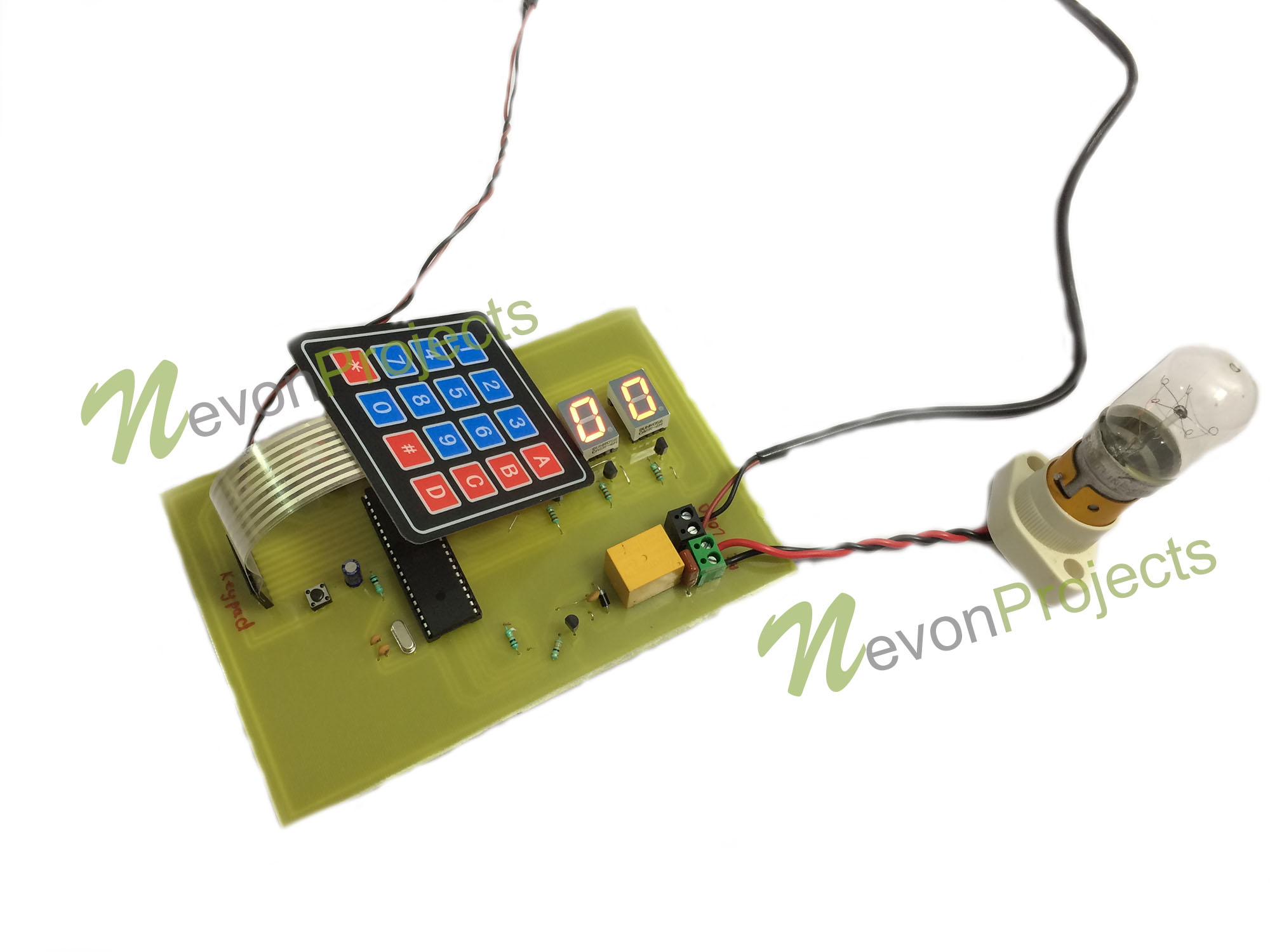

5. Assembly:

With all the

components in hand, it's time to assemble the gadget. This could involve

soldering electronic parts onto circuit boards, connecting wires, and fitting

mechanical components together. Precision and attention to detail are crucial

during this stage to ensure that the gadget functions correctly.

6. Testing

and Quality Control:

After assembly,

the gadget undergoes rigorous testing to ensure that it meets quality standards

and functions as intended. This could involve electrical testing to check for

proper voltage and current levels, as well as functional testing to verify that

all features work correctly. Any defects or issues are identified and addressed

during this stage.

7. Packaging

and Distribution:

Once the gadget

passes testing, it's ready for packaging and distribution. Engineers work with

packaging designers to create attractive and informative packaging that

protects the gadget during shipping and showcases its features to consumers.

The gadget is then distributed to retailers or directly to consumers, ready to

be enjoyed by users around the world.

Conclusion:

Making

electrical gadgets is a complex and fascinating process that involves

creativity, technical expertise, and attention to detail. By following

protocols like conceptualization, research and development, design, component

procurement, assembly, testing and quality control, and packaging and

distribution, engineers and inventors bring their ideas to life and create the

gadgets that enrich our lives every day. So, next time you use your favorite

electronic device, take a moment to appreciate the ingenuity and hard work that

went into making it possible!

Comments

Post a Comment